Service Hotline

Products

|

Classification |

Project |

KT18TA |

|

Sport control |

Maximum number of channels |

1 (2 is optional) |

|

Standard control axis number (standard configuration) |

5 |

|

|

Maximum number of control axes (optional) |

6 |

|

|

Maximum number of PLC axes |

3 |

|

|

Maximum number of spindles |

2 |

|

|

Maximum number of linkage axes |

6 (optional) |

|

|

Synchronous axis function |

Have |

|

|

Minimum control unit (mm) |

0.0001 |

|

|

Maximum number of workpiece coordinate system groups |

64 |

|

|

Maximum number of pre-read program lines |

1000 |

|

|

Maximum fast speed |

100000mm/min |

|

|

Maximum feed rate |

60000mm/min |

|

|

Macro program |

Macro program B |

Have |

|

Maximum number of variables |

256 |

|

|

PLC function |

Open PLC |

Have |

|

Desk I/O |

40/32 |

|

|

Maximum expansion I/O |

128/128 (optional) |

|

|

Communication |

USB |

Have |

|

SD card |

Have |

|

|

RS485 |

Have |

|

|

Ethernet |

Have |

|

|

Support workshop management system |

Stand by |

|

|

Servo Control |

Mechatrolink Ⅱ |

Have |

|

Eathercat |

Optional |

|

|

Compensation function |

Tool length compensation |

Have |

|

Tool nose (tool) radius compensation |

Have |

|

|

Backlash compensation |

Have |

|

|

Pitch error compensation |

Single, two-way |

|

|

Operating |

Handwheel trial cut |

Have |

|

go back |

Have |

|

|

Start at any point |

Have |

|

|

Breakpoint start |

Have |

|

|

Limited time boot |

Have |

|

|

Tool function |

Tool life management |

Time, frequency |

|

Maximum number of tool offsets |

32 |

|

|

Display |

Horizontal |

8 inches |

|

Vertical section |

10.4 inch |

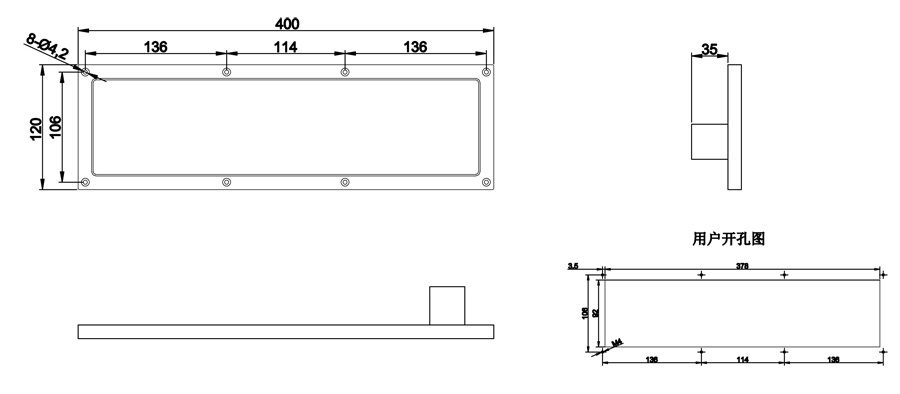

| KT18TA main panel installation size drawing |

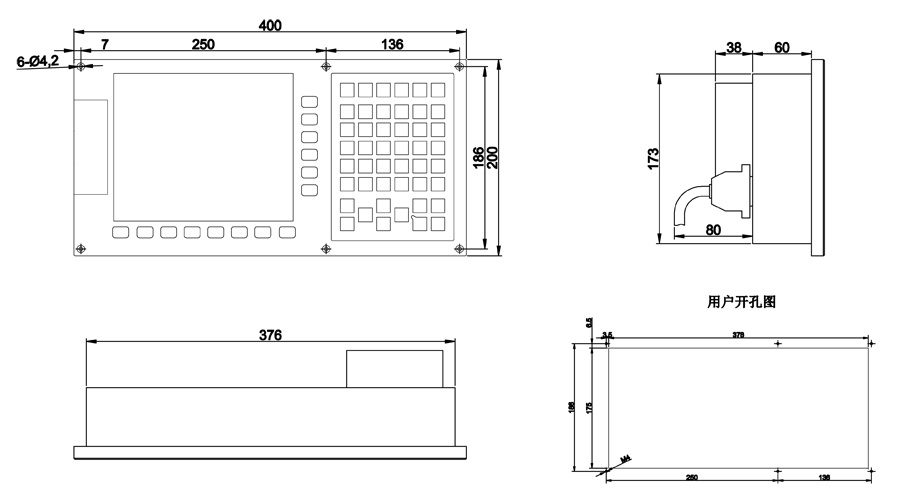

| KT18TA副面板安装尺寸图 |