Service Hotline

Products

|

Features |

Description |

Specification refers to the standard |

|

Control axis |

Number of control axes |

5-axis |

|

Number of linkage axes |

5-axis |

|

|

PLC control axis |

3 axis |

|

|

Input |

Minimum setting unit |

0.001mm and 0.0001mm optional |

|

Smallest moving unit |

0.001mm and 0.0001mm optional |

|

|

Maximum command value |

±99999999*minimum command increment |

|

|

Feed |

Maximum moving speed |

60000mm/min |

|

Thread lead |

0.001mm~500.000mm |

|

|

Automatic acceleration |

Front acceleration/deceleration linear type, |

|

|

Thread function |

Ordinary thread (following the spindle)/rigid thread |

|

|

Interpolation |

Positioning, |

Straight line, arc, thread cycle, tapping cycle, drilling cycle, |

|

Storage and |

Program storage capacity |

Electronic disk: 64M bytes |

|

Number of stored programs |

400 pcs |

|

|

Program editing |

Insert, modify, delete, copy |

|

|

Parameter storage |

Parameter backup, restore factory value, |

|

|

Display |

Horizontal |

8 inches, TFT true color display |

|

Vertical section |

8 inches, TFT true color display |

|

|

U disk function |

Program import |

Have |

|

Parameter import |

Have |

|

|

System U Disk Upgrade |

Have |

|

|

input Output |

Input port |

46 switches, photoelectric isolation input |

|

Output port |

38 switch output (OC output) |

|

|

Compensation |

Compensation function |

Tool compensation, backlash compensation, |

|

Canned cycle |

G94 |

Face turning cycle |

|

G93 |

External turning cycle |

|

|

G92 |

Thread cycle (straight and tapered threads, metric, inch, |

|

|

G70,G71,G72,G73 |

Compound loop |

|

|

G74 |

End face drilling cycle |

|

|

G75 |

Grooving or cutting cycle |

|

|

G33 |

Rigid tapping cycle |

|

|

PLC function |

PLC function |

Two-level PLC program, up to 8000 steps, |

|

Drive interface |

Yaskawa M-Ⅱ |

Control method: bus control |

|

Spindle |

Servo spindle |

Have |

|

Dual spindle function |

Have |

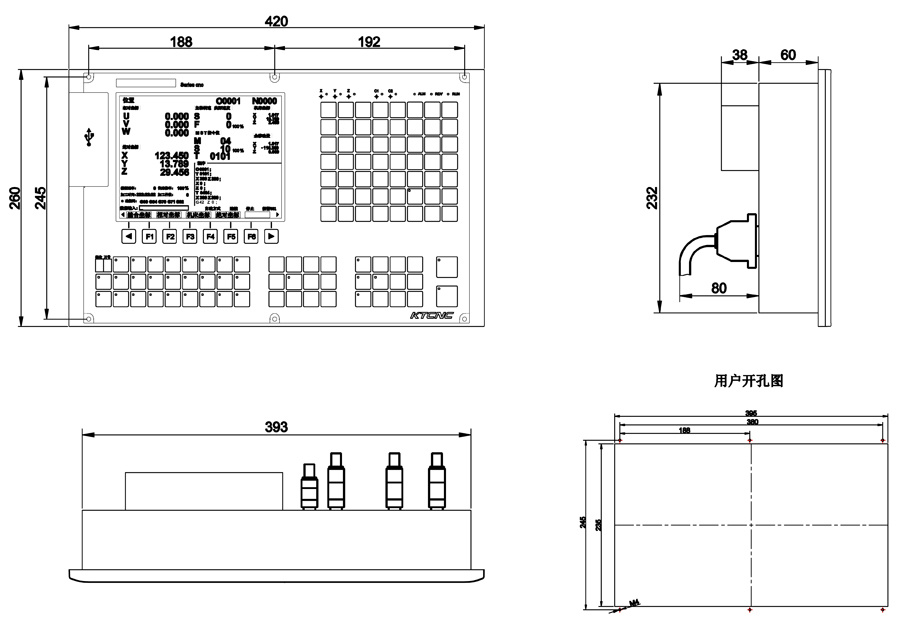

| KT838TI-C main panel installation dimension drawing |

| Software download | : | KT838Ti-C_Lathe axis software (L4C16159) | Download | |

| Manual download | : | KT838Ti-c_Lathe Instruction Manual_V1.0 | Download | Preview |

| Debugging instructions download | : | KT828(838)Ti-c_Debugging process description_V1.0 | Download | Preview |