Copyright: Nanjing Kaitong Automation Technology Co., Ltd. 苏ICP备11040710号 Power by: www.300.cn

Product Center

Product Search:

KT820TI

Page view:

Name

KT820TI

Features

Parameters

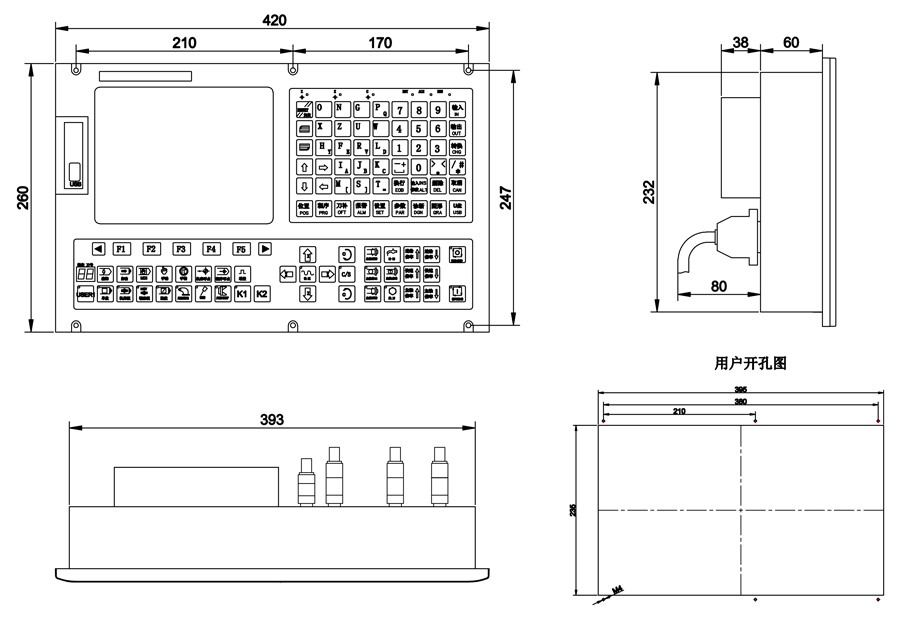

Installation Size

Application Cases

Related Download

• X, Z two-axis control, 0.001mm interpolation accuracy, support linear, arc, ellipse, and parabolic interpolation

• 2 channels 0~10v analog voltage output, support dual spindle control

• Support sentence-style macro command editing, support macro program call with parameters

• Equipped with a USB interface, which greatly facilitates the copying of processing programs and the import and export of system parameters

• Various threads can be turned, thread run-out length, thread cutting angle can be set

• It has multiple compound cycle functions such as tapping, deep hole drilling, grooving, inner and outer cylindrical surface, end surface cycle processing, etc.

• It has various special functions such as chamfering function, automatic repeat feeding, condition waiting, etc.

• Open clock function, piece counting function, and the time permission can be set when the equipment leaves the factory

• Electronic gear function. The motor can be directly connected with any pitch screw

• Built-in open PLC, you can adjust the parameters as needed to control the I/O port at will

• Backlash and pitch compensation function to maximize machining accuracy

• Large program capacity: 32M bytes, which can store 480 processing programs.

• 8.4"TFT800x600 dot matrix liquid crystal display, support full Chinese or full English menu display

• Can control all digital AC servo unit and three-phase vector subdivision stepping unit